Ensuring consistency of safety documentation

To ensure that different team (System, SW and HW) aligns to the same set of safety mechanisms (SM), Novotis uses a SM list. The SM list provides information about each safety mechanism is use, a unique identifier, the type of fault it addresses, and the design and diagnostic coverage.

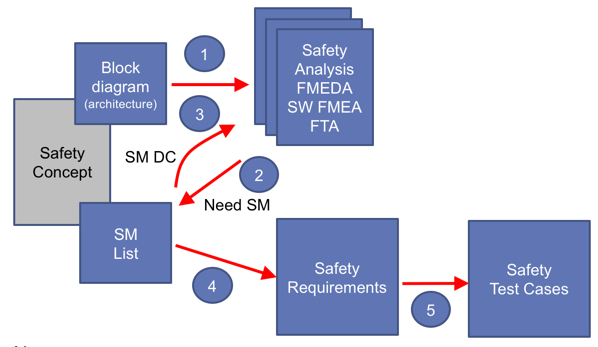

In a typical scenario the safety analysis may start with a simple high-level requirements like “do no cause unwanted actuation”. Based on an initial block diagram of the architecture the safety analysis identifies potential failures that could violate higher level safety requirements, (1) in the picture.

Needed safety mechanisms to detect and handle the faults are selected and added to the SM list (2). Each SM is given an identifier, e.g. SM02. The diagnostic coverage from the SM list will be used by the safety analysis (3). By entering a reference to the SM in each analysis consistency between the different teams are ensured.

Once the iteration around architecture – analysis – needed SM is finished requirements on SM can be formulated (4) and related test cases defined (4).

This will ensure a consistent and complete set of safety requirements even in the case of few and high level initial requirements.